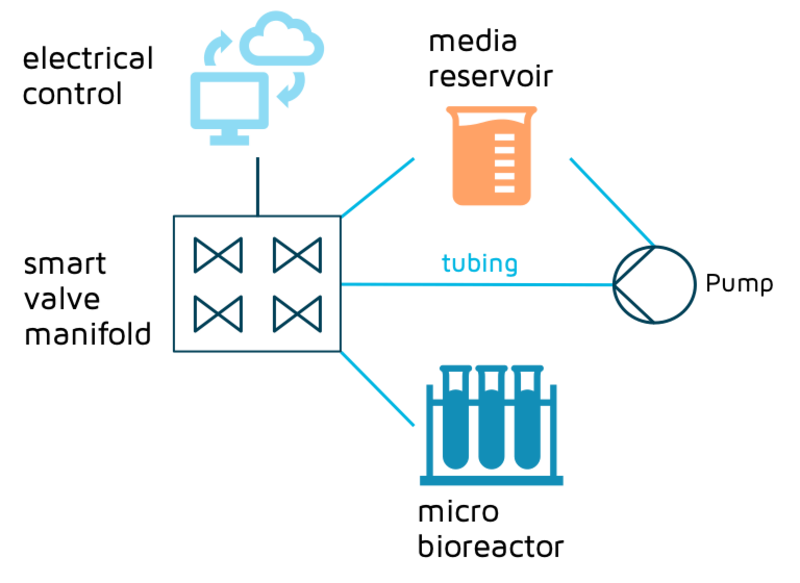

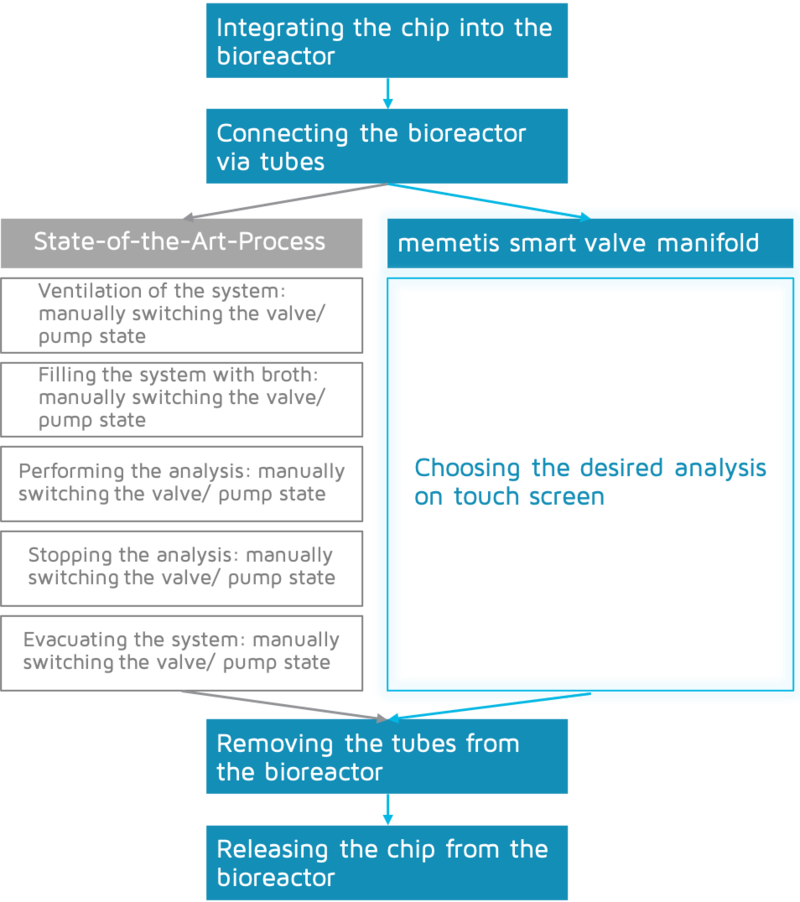

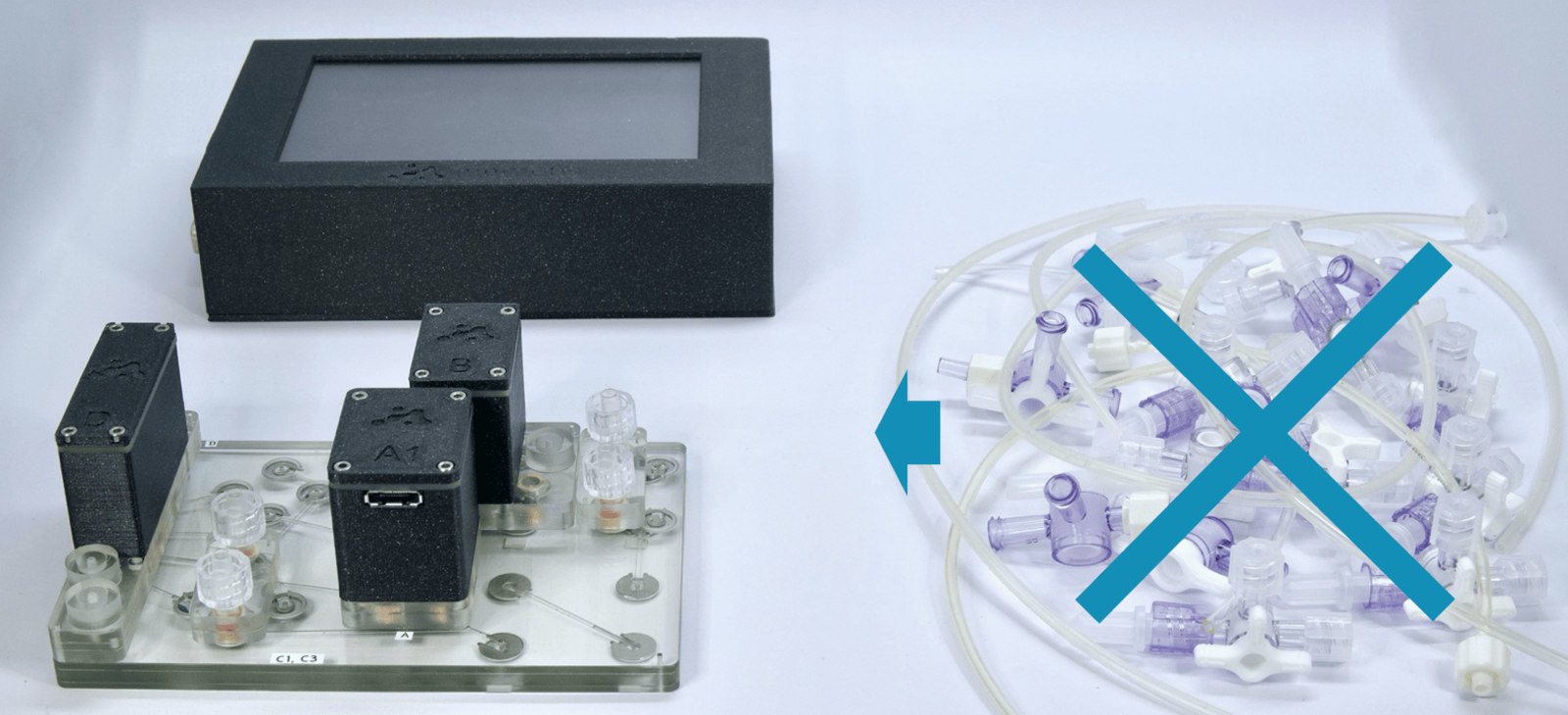

The smart valve manifold is integrated as a smart interface between the desired fluidic devices, like the microbioreactor and the media reservoir. The system can run self-sufficiently, once it is set up. Depending on the switching state of the valves, the microbioreactor is perfused from varying directions - laterally or vertically. This customer-specific use case can be adapted to various kinds of applications - applications where small amounts of liquids need to be controlled and space is limited. For example, for long-term experiments with lab-on-chips or applications in the clinical research field. In mobile devices for environmental analysis or mobile diagnostic devices especially needed in decentral, rural areas, memetis extremly small, light-weight valves offer decisive advantages.