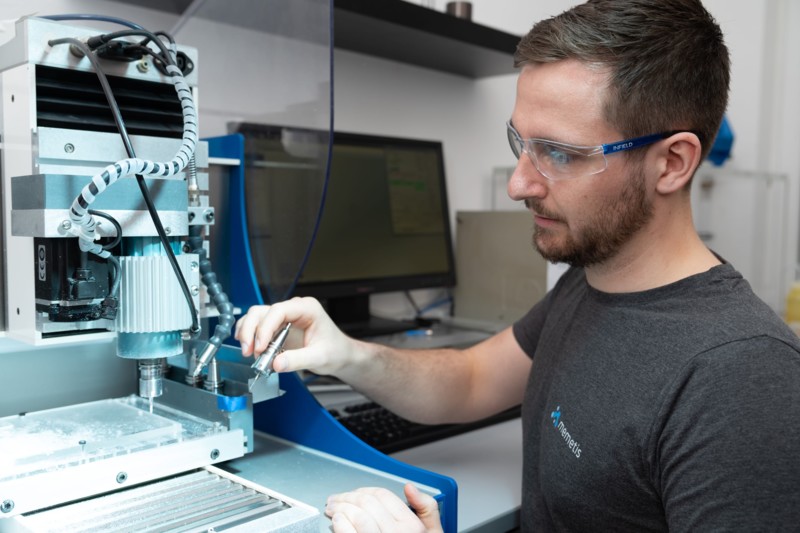

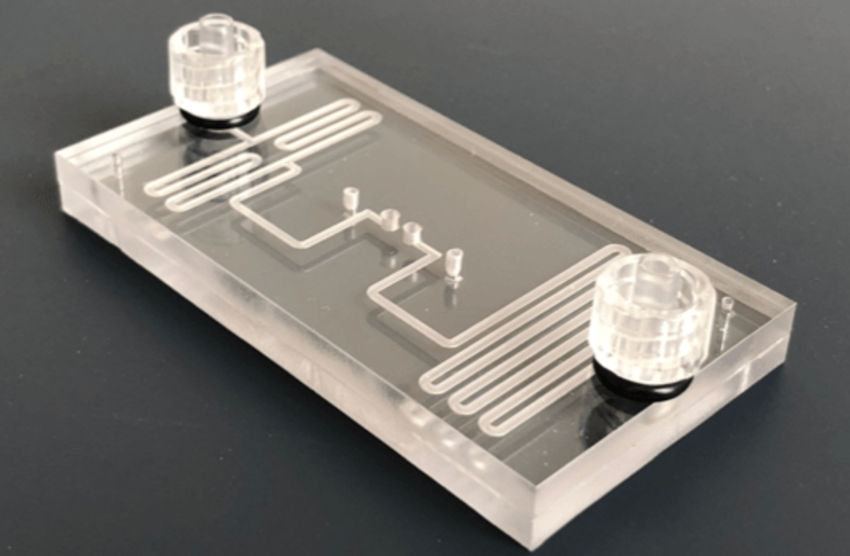

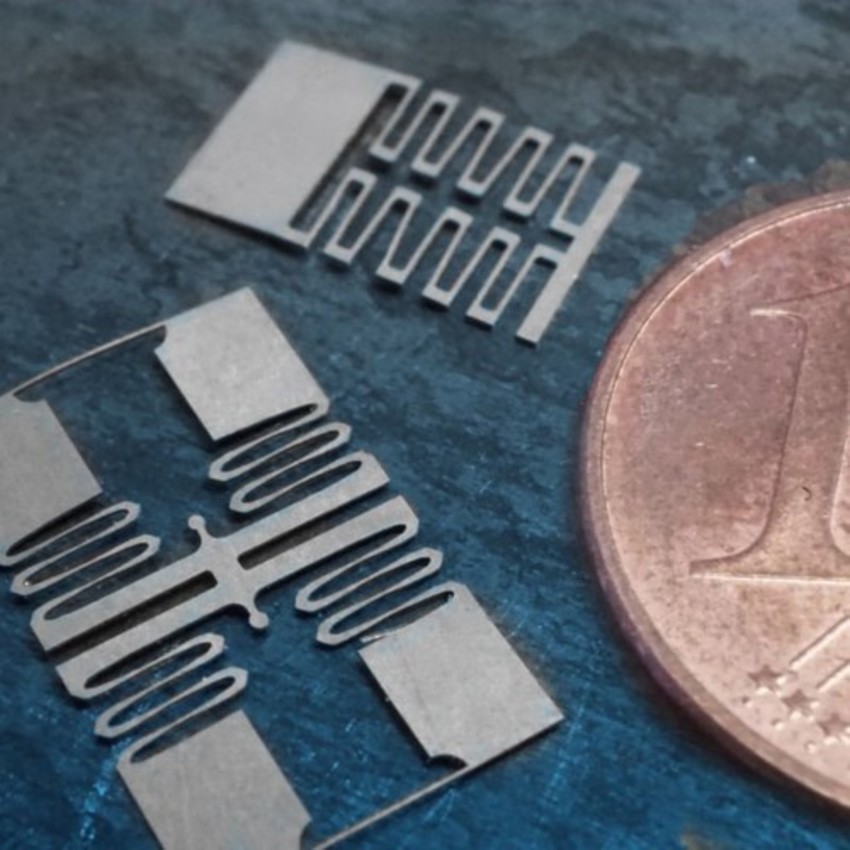

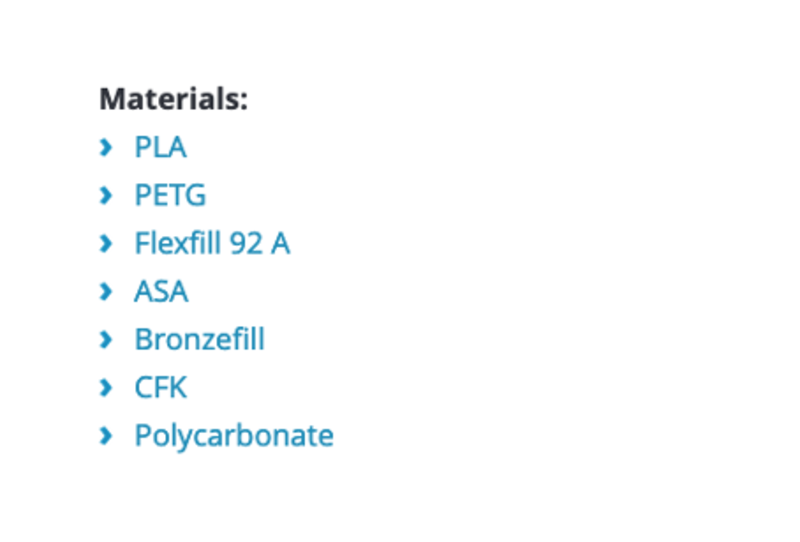

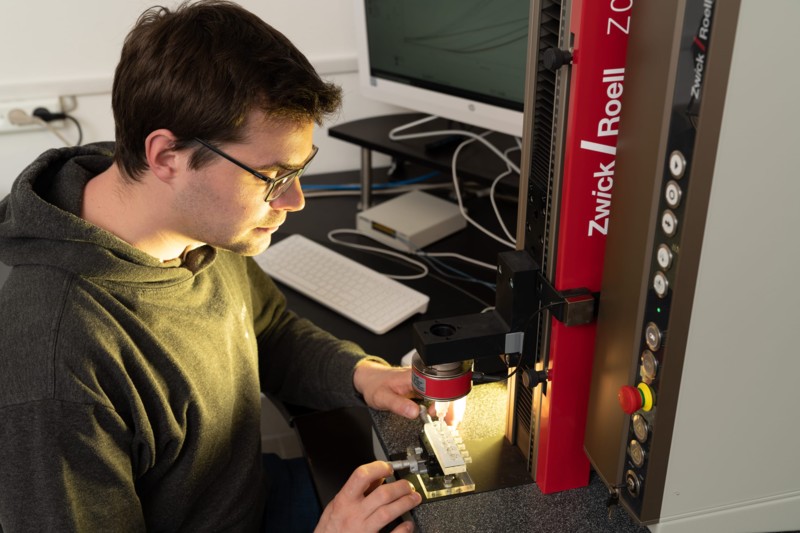

Due to our many years of experience in the field of milling, we can produce prototypes up to small series for you. On two different CNC milling machines with tool change, mainly polymer semi-finished products but also soft metals can be processed. Our core competence lies in the production of small structures/ dimensions (< 15 cm) with an accuracy of up to 5/100 mm. The choice of material is made with care according to your requirements and is not limited to polymers, just ask us.